Crystalline glazed pottery

An introduction to crystalline glazed pottery

Anyone who comes into interaction with crystalline glazed pottery is captivated by the pieces’ beautiful crystals and unique shapes. The glaze matrix, composed of zinc and silica, plays a pivotal role in creating the beautiful crystalline structures that adorn the surface of these pottery pieces.

From pottery to beautiful vases, every product displays an amazing variety of colors and patterns created by this amazing technique. Discovering these beautiful ceramic creations introduces a whole new world of creative expression and respect for the crystalline formations’ natural beauty.

These specially blended glazes have been developed to function beautifully at cone 5, offering amazing color depth and accuracy. Achieving the required crystalline effect requires precise control of the firing schedule and kiln temperature to promote crystal formation without overfiring.

The creation of small, needle-like forms inside the glaze is one of the most captivating features of crystalline pottery. These forms give each item an organic beauty and unique depth that makes it truly one-of-a-kind and fascinating.

Potters can unlock new possibilities for creating breathtaking crystalline pieces that captivate admirers with their intricate details by understanding the interplay between glaze composition, firing techniques, and kiln temperature.

History of crystal glazed pottery

The wonderful journey of discovery and creation that is the history of crystal-glazed pottery begins in ancient China. Over a hundred years ago, artists discovered the fascinating effect of crystal glazes and were amazed by how they could turn plain pots into glittering masterpieces.

Pottery lovers worldwide were amazed by the intricate designs and vibrant shades produced by this age-old method of glazing pottery. Still, it wasn’t until around a century ago that these glazes started to capture their attention.

Crystal-glazed pottery hasn’t always been perfect, despite its beauty. In the past, artists have had difficulty producing consistent work, and errors usually destroy their efforts. But these imperfections contributed simply to the appeal of crystal-glazed ceramics, as each piece displayed the distinct marks of the artist’s talent and dedication.

This art form’s rich history and timeless beauty still fascinate followers today, serving as a reminder that even imperfections may lend character and appeal to a lengthy past.

The role of specialty glazes

They offer really unique and freshly created formulas that are delicately passed for the best crystal-growing potential, specialty glazes are essential to the art of crystal growing. These glazes are colored with colorants that give the finished work more depth and visual appeal.

The strongest colorants are chosen with care to provide bright and lasting colors, producing beautiful crystalline forms. In the creative process, spray booths are essential for applying specialty glazes effectively, ensuring even coverage and precise application.

This lengthy process improves the final crystals’ overall quality and produces an impressive work of art that captures the attention of the viewer. Through the use of these particular glazes, artists can express themselves in new and creative ways via their stunning crystal creations.

Crystalline glaze & application

Obtaining success in the field of crystalline glazes requires a knowledge of the necessary instruments and processes. Every instrument, from application brushes to measurement scales, is essential to highlighting the unique beauty of crystalline effects.

It is also essential to use particular kinds of clay since some clay compositions are more suitable for the development and creation of crystals during the fire process. The firing schedule holds immense importance in crystalline glazing.

The temperature fluctuation during firing plays a pivotal role in shaping the outcome of the crystals. The controlled cooling process promotes crystal growth while avoiding cracking or other undesirable effects.

Clay body

High-fired porcelain makes a big contribution to the ceramics industry. High-fired porcelain’s clay body is specially designed to stand up to high temperatures without affecting its strength or visual appeal.

Because of its unparalleled strength and durability, high-fired porcelain is widely sought after for both beautiful and useful items. The process of high firing involves reaching temperatures of over 2300°F, resulting in a vitrified and non-porous surface that enhances the translucency and whiteness of the porcelain.

This exceptional level of refinement gives high-fired porcelain an air of elegance and sophistication that is unmatched by lower-firing techniques. Furthermore, the ability to achieve such high temperatures opens up opportunities for intricate designs and delicate details that truly elevate the artistry of each piece.

Glaze application

When it comes to glaze application, the impact on the final result is truly mesmerizing. The way the glaze interacts with the surface of the ceramic piece can create larger crystal formations that add a sense of grandeur and sophistication. These formations draw the eye and invite contemplation, adding depth and character to the finished product.

Smaller crystals within the glaze contribute a delicate intricacy to the overall aesthetic. They offer a captivating contrast to their larger counterparts and give each piece a unique and dynamic texture that captivates attention.

Unique color combinations in glaze application can elevate a ceramic piece from ordinary to extraordinary. When unexpected hues meld together in harmonious unity or bold contrast, they create an alluring visual tapestry that captivates both mind and eye. This infusion of color adds an extra layer of personality and vibrancy to each creation, making them stand out as exceptional works of art.

To Spray, Pour, Dip Or Brush?

The large 15-gallon bucket of glaze presents an exciting opportunity for artistic experimentation. Its abundant quantity offers the potential for multiple pours and layers, allowing artists to create intricate, textured effects on their pieces.

Creating patterns that are distinct and dynamic is enhanced by the uncertain aspect of dealing with a huge volume of glaze and its uneven pouring feature. Artists are asked to accept the freedom and mobility of the glazing process in light of this variety.

The options available to painters when applying this large amount of glaze include spray, pour, dip, or brush. Each method offers distinct advantages and challenges, requiring thoughtful consideration based on the desired outcome. Overall, the 15-gallon bucket of glaze opens up a world of creative possibilities for artists to explore and innovate within their craft.

The Art Of The Glaze

The process of crystal growth within a fired glaze matrix offers numerous benefits that elevate the art of pottery and ceramics. From creating intricate patterns to adding depth and dimension, the distinctive crystals form mesmerizing displays that captivate the eye.

This process produces finishes that are so versatile that one may be creative in numerous ways, from delicate lusters to amazing blasts of color. This transformative aspect of crystal growth adds a unique quality to each piece, making it truly one-of-a-kind.

The art of the glaze is all about celebrating the unexpected beauty that arises from this distinctive process. Each firing produces its own set of surprises, as the crystals form in unpredictable ways, resulting in an organic and enchanting finish.

Crystal glaze recipes vs ready-made

When it comes to glaze recipes, creating your own can lead to truly unique and stunning results compared to using ready-made options. While ready-made glazes are convenient, they often lack the depth and complexity that can be achieved through formulating your recipe.

By experimenting with different combinations of ingredients such as oxides, carbonates, and fluxes, you can create custom crystal glazes that are unlike anything available commercially.

Each ingredient has the potential to alter the final appearance of the glaze in unpredictable ways, leading to a sense of discovery and individuality with every batch. With patience and a willingness to experiment, artisans can uncover new ways to manipulate color, texture, and surface effects on their pieces.

– Sample crystal glaze recipe

– Louis Katz

Louis Katz is a well-known ceramic artist whose work has gained recognition for its unique crystal glaze effects. Using a combination of mineral compounds and firing techniques, Katz creates stunning crystal formations that emerge during the firing process.

One popular sample crystal glaze recipe involves mixing various oxides such as copper, cobalt, and iron with a base glaze to achieve different colors and crystalline effects. Artists can then apply the glaze to their pottery or ceramic pieces before firing them at specific temperatures to encourage the growth of crystals.

Firing crystalline glazed pottery

The firing phase is a crucial step in creating crystalline glazed pottery. Achieving specific temperatures in the kiln is essential to ensure the desired crystal formations in the glaze.

Different temperatures within the kiln play a pivotal role in controlling the crystallization process, influencing the size, density, and color of crystals that form on the pottery’s surface.

Kiln setters are invaluable tools that monitor and regulate temperature changes during firing, ensuring precision and accuracy. Reduction firing introduces a layer of complexity by altering the atmosphere inside the kiln, leading to unique color variations and effects on the crystalline glazes.

For those using manual kilns, mastering temperature control and timing becomes an art form, adding an element of personal connection and craftsmanship to each piece.

Temperature Accuracy

When it comes to ceramic materials, achieving optimal crystal growth is essential for creating high-quality glazed pieces. This involves precise temperature measurement and control during firing, especially at cone 10 and cone 12 temperatures.

Slow firing is often preferred to encourage the development of larger crystals, resulting in a more visually appealing finished product. Thinner shelves can also play a significant role in the firing process, as they allow for more even heat distribution and reduced warping of the ceramics.

Achieving temperature accuracy during firing can be challenging and has a direct impact on the outcome of the ceramics. The negative impact of inaccurate temperature measurement can result in unsuccessful crystal growth, leading to wasted time and resources.

With roughly $6,500 worth of materials at stake during a single firing cycle, the importance of precise temperature control cannot be overstated.

Glaze overflow & protecting kiln shelves

Kiln shelves play a crucial role in pottery and ceramics, but they often bear the brunt of glaze overflow. Using a catcher or collection dish beneath the shelves can be a game-changer for preventing damage caused by drips and spills.

This simple addition not only saves time on cleaning but also ensures that kiln shelves stay intact and ready for the next firing. For added protection, applying shelf primer before each use provides an extra barrier against glaze adhesion, making cleanup effortless and extending the lifespan of your kiln furniture.

By prioritizing these protective methods, potters and ceramic artists can preserve their investment in kiln shelves, leading to smoother firings, less maintenance, and overall improved productivity in the studio.

Is crystalline glazed pottery food safe?

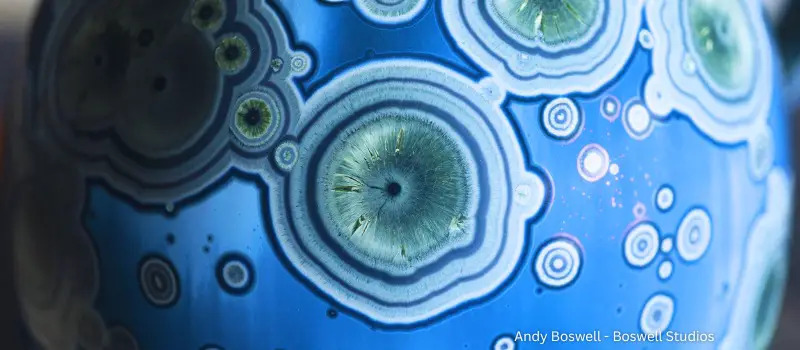

Andy Boswell’s creations at Boswell Studios have amazing visual appeal, but they also have remarkable functionality. His works have a unique depth and texture that are improved by the scraped metals he uses, giving them a sensitive and attractive quality.

Every piece is guaranteed to be food-safe and simple to clean thanks to Boswell’s liner coating, making it ideal for regular usage. Andy Boswell carefully avoided using crystalline glazes, which is a significant quality that differentiates his work.

Crystalline glazes are popular among potters due to their dazzling, multicolored effects, Boswell has decided to experiment with various methods in his works.

His creations have a unique twist from the lack of crystalline glazes, which makes them stand out in the field of ceramics and pottery.

By using a liner glaze instead of crystalline glazes, he was able to maintain food safety regulations while showcasing the diversity and potential within the field of ceramic artistry—a notable monument to his devotion to producing wonderfully.

Joanna miller

Clay Maven

Joanna Miller, also known as the Clay Maven, has made a name for herself as an artist and educator in the world of ceramics. Her unique approach to working with clay has captivated hobbyists and professionals alike, drawing them into the magical substance that is both squishy and malleable.

What sets Joanna apart is her ability to bridge the gap between beginners and experts, offering fresh insights and techniques that engage even the most seasoned ceramic artists. Working with clay attracts because of its fundamental possibilities as well as its aesthetic qualities.

Joanna encourages students to explore and push limits in their works, emphasizing the importance of accepting the material’s inherent enchantment. She creates intricate sculptures as well as straightforward hand-built creations that astonish and attract the interest of both professional and aspiring artists.

Conclusion

The art of creating crystalline glazed pottery is akin to an enchanted dance between science and art. The exquisite crystal formations that emerge from the kiln hold an otherworldly allure, drawing our eyes into a mesmerizing display of color and texture.

Each piece tells a story of its own, capturing the magic of natural phenomena within the confines of carefully crafted clay. The delicate balance of chemical compositions and firing techniques required to achieve such stunning results serves as a testament to human ingenuity and creativity.

Crystalline glazed pottery is an embodiment of wonderment and skill, inviting us to explore new dimensions of artistic expression.

What is the purpose of glazing?

The glazing contributes both to the thermal performance of a window and its impact resistance.