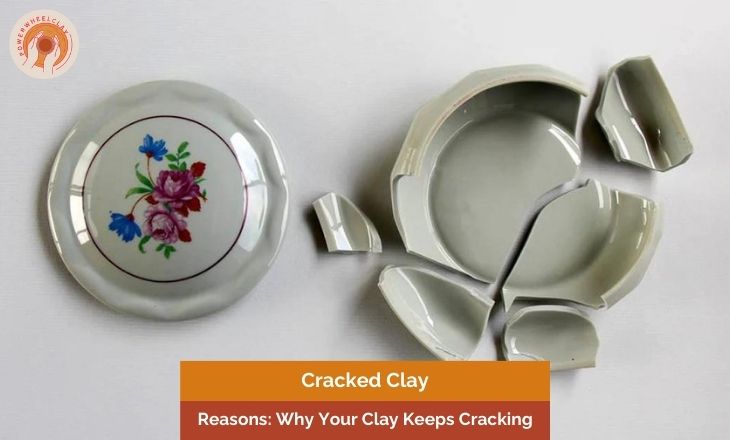

6 Causes Of Clay Cracking In Pottery

Pottery has long been celebrated for its ability to capture the beauty of imperfection, but these imperfections can be more frustrating than charming cracks in clay. The causes of clay cracking in pottery are crucial for artists and enthusiasts alike. It is the difference between a masterpiece and a shattered disappointment. we learn about six key factors contributing to pottery cracking.

What Causes of Cracks in clay?

Clay Cracking in pottery is a common problem due to various factors, primarily related to the physical and chemical properties of the soil. One of the main causes of clay cracks is excessive dryness and lack of moisture in the soil. When clay soil dries out, it contracts, leading to the formation of cracks on its surface.

This process is further exacerbated by high temperatures and prolonged exposure to sunlight, accelerating water evaporation from the soil. The mineral composition of clay also plays a crucial role in its propensity to crack. certain types of clay minerals tend to swell when they absorb water and shrink when they dry out, resulting in significant cracking.

Not Properly Wedging Clay

The causes of cracking clay in pottery can often be traced back to improper wedging techniques. When wedging is not carried out effectively, air pockets can become trapped within the clay, leading to potential cracks as the piece dries and is fired.

If the clay has not been properly aged or has an inconsistent moisture content, it may dry unevenly and lead to cracks during firing. Proper wedging techniques and careful preparation – are integral in preventing cracking clay in pottery.

Uneven-Drying Clay Can Cause Cracking

Uneven drying can lead to cracks as the outer layer dries quicker than the inner core. This imbalance in moisture levels strains the structure, leading to unsightly fissures and fractures. excessive sun exposure or warm air can accelerate this process, exacerbating the risk of cracking.

Clay that has not been uniformly mixed or lacks sufficient plasticity is more prone to developing cracks during the firing process. Thus, skilled handwork and meticulous attention during the early stages of pottery-making are crucial in preventing these issues from arising.

Uneven Wall Thickness Can Cause Cracking Clay

Uneven wall thickness can cause cracking clay as differing densities within the material result in unequal levels of contraction and expansion during drying and firing. This imbalance strains the clay, leading to the development of cracks as it attempts to adjust.

Excessive water content in the clay can be a significant contributor to cracking. During the drying process, uneven evaporation can occur when a piece has thick and thin areas, causing stress within the material. This stress creates internal pressure that ultimately leads to crack formation. Pottery artists must carefully manage their clay’s moisture level throughout all stages of creation to ensure uniform drying and prevent cracking.

The Type Of Clay And Its Plasticity Can Cause Pottery Cracks

Clays with low plasticity, such as stoneware, are more likely to crack during drying and firing due to their inability to stretch and bend without breaking. The clays with higher plasticity, like ball clay, are better able to withstand the stresses of forming and firing without developing cracks.

Another key factor contributing to cracks in pottery is inadequate preparation or handling of the material. Insufficient wedging or kneading of the clay can result in air pockets being trapped within the material, causing weak spots that may lead to cracks during shaping or firing.

Improper storage and drying techniques can exacerbate this issue – rapid drying of the clay can cause uneven shrinkage and subsequent cracking, emphasizing the importance of controlled drying processes in pottery production.

Inconsistent Kiln Firing

When the temperature within the kiln fluctuates, it can result in uneven heat exposure on the pottery piece, causing stress within the clay structure. This stress manifests as cracks that compromise the integrity of the artwork and often lead to unsightly flaws.

Rapid temperature changes during cooling after firing can also contribute to cracking clay. If the pottery cools too quickly or too slowly, it creates tension in the clay body, giving rise to fissures and breakage. Achieving a controlled cooling process is crucial in preventing this issue

Poorly Joined Joints

When the clay isn’t properly fused, it leaves weak spots that are susceptible to stress and temperature changes, leading to unsightly cracks. Improper drying techniques can exacerbate this issue. If the pottery dries too quickly, or unevenly or if excess moisture is trapped inside due to poor ventilation, the stress from drying can cause cracking.

Using excessive force during the shaping or construction of the pottery can also lead to compromised joints and an increased risk of cracking. Potters must handle their pieces delicately and with finesse to avoid accidentally weakening their structures during production. Paying close attention to joint quality and ensuring proper drying techniques can mitigate these causes of cracking clay

How Do You Keep Pottery From Cracking?

Keeping pottery from cracking requires careful attention to various factors during the entire process. It’s essential to ensure proper wedging of the clay to eliminate air bubbles that can lead to cracks. Maintaining an even wall thickness throughout the piece is crucial in preventing uneven stress that can cause cracking during the drying and firing stages.

Selecting appropriate glazes and firing techniques tailored to the specific type of clay used can significantly impact the pottery’s resilience against cracking

Conclusion

Clay cracking in pottery is multifaceted and requires careful consideration by potters and ceramicists. Each case presents a unique challenge that can impact the quality of finished pieces. Understanding these causes and implementing appropriate preventive measures is crucial for creating durable and visually appealing pottery.

Artisans must invest time in mastering the art of handling clay to ensure their creations’ integrity and preserve their craft’s beauty for generations to come.

FAQs

What To Do When Clay Cracks?

you can try repairing any cracking that has occurred by adding a few drops of water to the crack and smoothing it with your fingers. You may also try filling in the crack with a small amount of wet clay and smooth with your fingers.

Which Clay Doesn’t Crack?

Air-dry modeling clay does not crack. The air clay will be hard on the surface to keep its outward appearance, and it will be lighter after drying.

Why does Ceramic Cracking?

Cracking is mainly caused by uneven drying of the piece, meaning that some parts of the pottery shrink more than others. Create a consistent environment for drying the piece and undertaking the necessary preparation to ensure that the entire piece dries at a similar rate.

why Is My Clay Cracking?

It’s caused by shrinkage because of the loss of the water inside the clay body. Cracking in air dry clay is typically caused by sculpting over an armature or using a lot of water,