Bisque Ceramics: A Short Guide

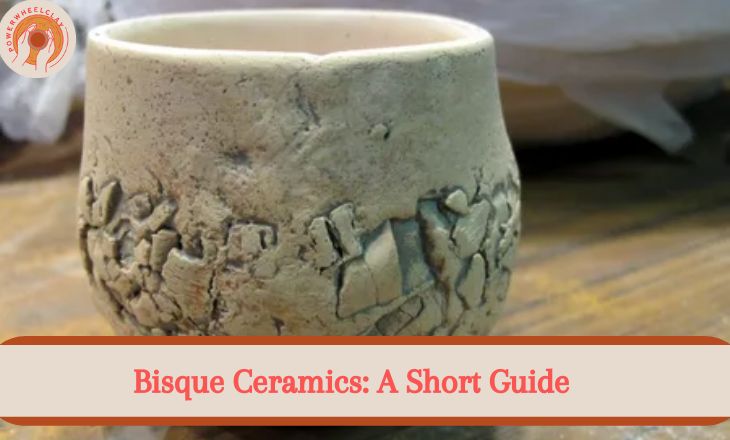

In the clay area, Bisque Ceramics definition is an effective and practical option. Clay that has been heated once at low temperatures, keeping it firm however weak, is also known as bisque. The purpose of this first fire is to blow out the clay and make it ready for more firing and painting.

What Is Bisque Pottery?

One of the seven stages of pottery is called Bisque Pottery or bisque ware. A type of weak fire is clay heating. Clay clay forms through the firing step to create clay pots. The word “bisque” is the French word “twice-baked” or “twice-cooked.” Because we discuss pottery, the term heating is key for us.

Clay-prepared pottery is not the last step. Because clay-prepared Bisque pottery is weak, water may enter into it. It is not practical to store water in a weak boat. The potter typically will finish, color, or paint a pot after it has been fire-heated. The pot will be destroyed once more at a higher level.

In bisque ceramics, the word “bisque” can be found in several meanings. The meaning of the word and its main uses are as follows:

- Bisque Firing: An important stage in the creation of the bisque ware firing presents a special chance for artists to investigate the transformational effects of heat on clay.

- Bisque: A Bisque is a strong pottery cup that received one fire. Another word for clay is a weak condition that is good for painting. A potter then burns the Bisqueware Clay once more if it is painted. At this point, the vase is formally in the glaze ware clay stage.

Once glaze ware, the thing can be used for drinks. Bisque clay definition is a type of square ceramic material that has been fired once before being glazed or decorated. This initial firing process removes all moisture from the clay, making it hard and porous, ready for further work

- Bisque Ware:

After being fired, an item is in this condition. It is sometimes known as “biscuits china” or “biscuit ware.” A piece of bisque ware stays in its clay form, which is why it is called ” Bisqueware clay.

Bonus: Bisque Porcelain

China clay, also known as China white, is a common finished type in Europe. Pottery achieves a soft look after it is fired and heated. Because it has a stone’s end I’ve seen it used for figures and statues.

Bisque Firing

The Bisque Firing stage, which is the very first heating that a pottery object experiences, is an important step in almost all clay methods. It looks like it has many goals.

- Firstly, it converts clay into a ceramic through modification of its nature. It is open and keeps its form. It’s also prepared for painting. For the glaze of ceramic to flow through the whole piece, there must be an open interior

- Second, the pot is ready for high temperatures during the last fire by using any extra water destroyed during the first fire. Even cooling and burning are two of the main causes of plaster breaking. The use time for clay is low. There is less water present and the drum has less stress.

- Third, clay paint and coats belong more successfully to clay bases thanks to clay fire.

Bisque Firing Temperature

Burning Ceramics typically takes place at a low fire heat. It can also be used to fire different glazes, and the “low” burning frequency is usually used for bisque firing.

The low-firing pyrometric devices are 010 to 02. That translates to a cone ranging from 1636° to 2052°F. For all of us, low heat in clay translates to high heat.

Thin clay objects can be made at a lower temperature (cones 010–08). For anything you wish to glaze, this works best. Conversely, your products will become less elastic and more solid on the higher end (cones 07–04).

How Long Does It Take To Bisque Fire?

A basic fire needs ten to twelve hours to complete. The clay pieces experience chemical changes that result in bisque ware all over those about ten hours. When clay fires, keeping to a fire cycle is important. If not, a kiln explosion might destroy all of your hard work.

The kind of fire you decide is going to influence how the base fire method plays out. You will often utilize an electric or gas kiln.

- The following is a general outline for each firing stage:

- Heat off the firebox slowly. Then up the setting by putting on the fire. Your pot cannot be in the fire heating up; instead, it should be in its final drying stage. At low heat, for two to three hours. Put your goods into the firebox after it starts to warm up. The oven needs to slowly warm up for about two hours.

- Boil for two to three hours on low. For program kilns, there is nothing to be achieved here. If you have a window, you can look at your pottery. Keep your goods on low heat for an additional two hours.

- At a higher temperature for two to three hours. This is not the same as “high fire,” which means heat at the level of commerce. it’s an indicator of the kiln’s speed of heating. Once more, each container has to get about two hours in the fire.

- When working with a fire, it’s beneficial to use observe poles or polymeric poles. When you’re waiting a long time for the components to finish, they could help you keep on the path.

- Allowing the firebox to cool down with the goods is the last step. After the oven cools off, open the door and enable the air to come up to room heat for a few hours longer. This will allow you to remove your bisque-fired pots.

Shrinkage During Bisque Firing

Your pots can decrease at any time after the clay’s plastic stage. There is no ignoring it. On the other hand, your pots should not drop significantly after bisque firing. They are likely to break if they do. They must be in the bone-dry phase of the clay before throwing them in the kiln for this reason. If not, the goods may decrease easily, leaving the boat to be in a great deal of tension.

Glazing Bisque And Other Decoration

After clay work, a lot of makers will coat, enhance, or color their work of art. As this article has repeatedly said, a clay pot is an unusually thin dish. This shows that decorations such as paints, coats of glaze bisque, and others attach to the pottery face well.

Paint made with acrylic is the perfect color to use. The color and finish you want for your creation will decide on the best style of glaze bisque. Bisque ceramics definition refers to a type of pottery that has been fired once at a low making pottery without a Kiln any glaze applied.

If you want to use your clay product to contain water, you must complete this step. Any liquids you put in the jar will be taken in by the open clay body. Making your pot safe for use includes clay glazing and glaze burning it.

Conclusion

Bisque Ceramics provides a singular platform for creativity. Working with unused, soft clay allows for rich forms and finishes that are a touch of joy for both fans and painters. The bone in the empty pot increases quality from this.

Bisque Ceramics offers a unique and versatile medium for artists and crafters alike. With their porous nature and ability to absorb glazes and paints, bisque pieces provide endless opportunities for creativity.

FAQs

What Is The Difference Between Greenware And Bisque Ceramics?

Greenware and bisque ware ceramics definitions are both stages in the process of creating ceramic pieces, but they differ in terms of their state of completion.

What Is Bisque Clay?

Bisque Clay definition is a type of clay that has been fired once at a low temperature, typically around 1650°F.