Pottery making is a timeless art form that requires precision, patience, and a touch of creativity. One essential tool that can revolutionize your pottery wheel experience is the humble bat. No, not the flying mammal, but rather a round disc made of wood, plastic, or plaster that sits atop the wheel head to provide a stable surface for clay work.

Bats come in various shapes and sizes, each serving a specific purpose in aiding potters to create beautiful and functional pieces with ease.

Here Are 5 Tips on How to Use Bats on a Pottery Wheel:

The type of bat you choose to use on a pottery wheel can greatly impact your work. Plaster bats are excellent for moisture absorption while plastic bats offer durability and ease of cleaning. Selecting the right bat for each project can enhance your overall pottery experience by providing stability and support during throwing.

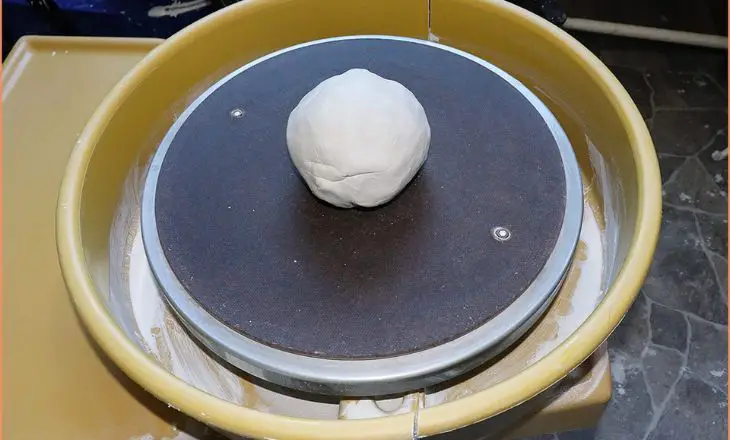

To prep a bat for use, ensure it is clean and free of debris that could cause wobbling or imbalance. Before attaching the bat to the wheel head, lightly wet the surface to create suction for better security. When attaching a bat, make sure it sits firmly on the wheel head without any gaps to avoid potential mishaps during throwing.

Removing a bat from a pottery wheel requires care to prevent damage or warping. Gently loosen any clay residue around the edges before lifting off the bat in one smooth motion. Once finished using your bats, store them vertically in a dry location to maintain their flatness and prolong their lifespan for future projects.

Types of Bats for Pottery Wheels

To choose the right type of bat for your pottery wheel, there are several options available to cater to different preferences and needs. Plastic bats are lightweight and durable, making them a popular choice for beginners or those who prefer easy cleaning and maintenance. Wooden bats provide a more traditional feel and can offer a natural aesthetic to your pottery work, although they may require more care in terms of moisture protection.

Masonite bats are known for their smooth surface that helps clay adhere easily while working on the wheel. Medex bats combine the durability of plastic with the smoothness of masonite, providing a versatile option for potters of all skill levels. Plaster bats are excellent for absorbing excess moisture from the clay, aiding in drying out pieces faster and preventing warping during the firing process.

Each type of bat has its unique advantages, so considering factors like material properties, cost-effectiveness, and personal preference can help you make an informed decision on which type would best suit your pottery practice.

Now, let’s look at some types of bats and the pottery wheels they are compatible with:

Masonite Wheel Bats

Masonite wheel bats are a popular choice among potters for their durability and smooth surface. There are various types of bats available for pottery wheels, each serving different purposes. For example, round Masonite wheel bats are ideal for throwing larger pieces or bowls as they provide a stable surface to work on. Similarly, square Masonite wheel bats are great for creating plates or tiles due to their flat edges allowing for easy trimming and shaping.

Another type of bat that is commonly used with pottery wheels is the textured Masonite wheel bat. These bats come with a roughened surface which helps in preventing clay from sticking during the throwing process. This texture also adds an interesting element to the finished piece by leaving unique marks on the bottom side of the pottery.

Masonite Bats Are Available In Two Varieties:

Masonite wheel bats come in two varieties: tempered and non-tempered. The tempered bats are coated with a thin layer of linseed oil, making them smoother and more water-resistant than their non-tempered counterparts. This feature allows pots to be easily removed and dried after throwing, enhancing the overall efficiency of the pottery-making process.

Non-tempered bats lack the linseed oil layer, resulting in a less smooth surface. It is recommended not to leave pots to dry on these bats as they may absorb moisture and compromise the quality of the finished product. If you find your bat warped, a simple fix involves placing it on a flat hard surface with the curved side up and placing a heavy object like a cinder block in its center for about a day, allowing gravity to restore its shape effectively.

Plastic Wheel Bats

Plastic wheel bats are a popular choice for many potters due to their durability and ease of use. There are several types of bats that can be used with plastic wheel bats, each offering unique advantages for the potter.

One common type is the round bat, which provides a smooth surface for throwing clay and makes it easy to remove pots without damaging them. Another type is the square bat, which offers more stability and support for larger pieces. There are contour bats available that are shaped to fit specific pot sizes or shapes, enabling precise trimming and finishing.

Overall, the variety of bat types available for plastic wheel bats allows potters to customize their pottery-making experience and achieve optimal results in terms of efficiency and quality. Experimenting with different types of bats can help potters discover new techniques and improve their craft.

Plastic bats offer convenience and durability in pottery wheel use, with features that enhance the throwing process. The textured surface of Amaco Plastic Bats aids in clay stability during centering, while the smooth side requires a gentle touch to prevent slipping. These bats are an investment for potters seeking long-term usability and reliable performance in their work.

Speedball Plastic Bats’ innovative rim design makes them easy to handle and remove from the wheel, adding a practical dimension to their functionality. The injection molding process ensures uniformity and compatibility with various wheel sizes, providing versatility for different pottery projects.

Medex Wheel Bats

Medex Wheel Bats offer a durable and eco-friendly option for pottery enthusiasts. The premium MDF material used in their construction not only provides a sturdy surface for clay work but also ensures minimal environmental impact through its high recycled content. The slight absorbency of Medex Bats allows for the proper adhesion of clay without the risk of warping, offering a reliable support system for your pottery projects.

One key advantage of Medex Bats is their compatibility with various pottery wheels that have bat-pin heads, making them versatile and practical tools for artists of all skill levels. By avoiding excessive water exposure, users can prolong the lifespan of these bats and continue to enjoy their benefits over time.

Medex Wheel Bats stand out as a reliable choice due to their sustainable composition, durability, and compatibility with different pottery wheel models. The unique characteristics of these bats make them a valuable addition to any potter’s toolkit, offering both functionality and longevity for creative endeavors in clay artistry.

Plaster Wheel Bats

These bats excel in preventing cracking on pottery, making them a valuable tool for achieving flawless results. Their absorbent nature, owing to the use of pottery plaster in their construction, sets them apart from other types of bats available in the market. Despite being thicker and heavier than plastic bats, plaster bats offer longevity and stability on pottery wheels that lack bat-pin holes.

Crafting your own plaster bats can be a straightforward process with minimal requirements. By using Pottery Plaster and a rubber mold, potters can easily create custom-sized bats tailored to their individual needs. With the versatility and durability that plaster wheel bats bring to the table, they present an enticing option for potters looking to enhance their craft without compromising on quality or performance.

Hydro-Bats

Hydro-bats are revolutionizing the pottery world with their innovative design and enhanced functionality. The use of hydro-stone, a durable gypsum material, elevates these bats above traditional plaster options in terms of strength and longevity. With rubber pin grommets for secure attachment to the wheel, hydro-bats provide stability and ease of use for potters of all levels.

One standout feature of hydro-bats is their superior water absorption capabilities, allowing for smoother throwing and shaping processes. The reduced need for cutting wire during removal not only streamlines the workflow but also reduces material wastage. This combination of efficiency and durability makes hydro-bats a game-changer in pottery studios.

Plywood Bats

Plywood bats offer a convenient option that can be made at home, it’s essential to handle them with care to prevent warping. Plywood bats strike a balance between water absorption and weight, making them ideal for throwing large pottery without losing their shape. By ensuring proper drying post-use, you can extend the lifespan of your plywood bat and maintain its functionality over time.

It’s fascinating how different materials behave on pottery wheels, with each offering unique advantages and challenges. Plywood bats provide a reliable surface for creating larger pieces due to their sturdiness and lightweight nature. Understanding the characteristics of plywood bats compared to alternatives like Masonite and Medex allows potters to make informed decisions based on their specific project needs.

How To Prep A Bat For The Pottery Wheel

To prep a bat for the pottery wheel, it’s crucial to achieve the right level of moisture. If the bat is too wet, the clay might slide around and not adhere properly, leading to frustrating results. But, if it’s too dry, the clay won’t stick well either. Finding that perfect balance is key to creating smooth and successful pieces on the pottery wheel.

One way to ensure your bat has the ideal moisture level is by lightly spritzing it with water before placing your clay on top. This simple step can make a significant difference in how smoothly your pottery creation progresses. Remember, consistently checking and adjusting the dampness of your bat throughout your work can ultimately save you time and effort in achieving your desired outcome.

Scrap Off Any Clay That Remains On The Bat

After throwing pottery, it’s crucial to clean your bat effectively for optimal results. Ensure that any leftover clay is scraped off the bat surface using a metal rib tool or a plastic scraper. This not only maintains the cleanliness of your tools but also prevents any unwanted textures in future pieces. By removing excess clay, you create a smooth and even surface for your next project, allowing your work to be more uniform and professional-looking.

Leaving clay residue on your bat can lead to issues such as warping or uneven drying of subsequent pieces. A clean bat promotes stability during the throwing process and helps maintain consistency in thickness across your pottery items. By regularly cleaning off the remaining clay, you prevent contamination between different types of clay and glazes. This simple step not only enhances the longevity of your tools but also improves the quality of your finished ceramics.

Wipe The Bat Using A Damp Sponge

One effective way to clean a baseball bat is by using a damp sponge. This method helps to remove dirt, debris, and sweat that can accumulate on the bat during gameplay. The damp sponge can easily reach into the grooves and crevices of the bat, ensuring a thorough cleaning process.

To wipe the bat using a damp sponge, simply moisten the sponge with water and gently scrub along the length of the bat. Be sure to pay extra attention to areas where dirt is more likely to build up, such as around the handle and barrel. Not only does this method help maintain the appearance of your bat, but it also helps ensure better grip and performance during play.

Incorporating regular cleaning practices into your baseball equipment maintenance routine can help prolong the life of your bat. By wiping down your bat with a damp sponge after each use, you can keep it looking new and performing at its best for many games to come.

How to Attach a Bat to a Pottery Wheel

When attaching a bat to a pottery wheel using the bat-pin method, ensure that the pins are securely inserted into the indentations on the wheel head. This method provides stability and prevents any wobbling during throwing. For those using the clay pad method, make sure to wet the pad slightly before placing the bat on it to create a strong bond between the two surfaces.

A properly attached bat is crucial for successful pottery making, as it provides a stable foundation for your clay work and allows for smooth rotation while shaping your pieces. Remember, attention to these details will result in better quality pottery with fewer mishaps along the way.

Bat-Pin Method

The Bat-Pin method is a popular technique used by potters to securely attach a bat to a pottery wheel. By aligning the holes on the bat with the pins on the wheel head, potters can easily remove and replace bats during their throwing process. This method ensures stability and prevents any unwanted movement while working on the wheel.

One advantage of using the Bat-Pin method is its versatility – potters can use different sizes and types of bats depending on their project needs. This technique allows for quick adjustments and ensures that the bat stays firmly in place even when working with heavy clay.

As potters continue to innovate and experiment with different techniques, the Bat-Pin method remains a fundamental aspect of pottery wheel usage. Its simplicity and effectiveness make it an essential skill for ceramic artists looking to elevate their craft.

To Attach Your Bat To The Pottery Wheel

A stable base is crucial for creating beautiful pieces of pottery. The Bat-Pin method offers a simple yet effective solution to attach your bat securely to the pottery wheel. By ensuring the bat-pin heads are securely in place on the wheel and aligning the bat holes with these pins, you set the foundation for a steady working surface.

Placing the bat on the wheel and patting it gently might seem like minor steps, but they are essential in preventing wobbling during your creative process. This method not only provides stability but also allows for smooth rotation as you mold and sculpt your clay.

Clay Pad Method

The Clay Pad Method offers a creative solution for potters facing challenges with attaching bats to their pottery wheels. This technique is particularly useful for those without bat-pin holes or who prefer not to drill into their equipment. By using a clay pad, potters can secure the bat in place and prevent wobbling, especially when working on larger pieces.

While it may be slower than other methods, the clay pad approach showcases the adaptability and resourcefulness of pottery artists in problem-solving situations. One benefit of the Clay Pad Method is its versatility, fitting both pinhead and non-pinhead pottery wheels.

Here’s How To Make The Clay Pad To Attach Your Bat To The Pottery Wheel

Creating a clay pad to attach your bat to the pottery wheel can be a simple and efficient process. By spinning your pottery wheel and slamming a small chunk of clay onto it, you lay the foundation for a sturdy connection. Using the pressure from your knuckles and hands, shape the clay into a flat plate-like structure that will securely hold your bat in place.

The versatility of the clay pad method lies in its adaptability to different pottery wheel sizes and bat types. Whether you’re working with a large or small wheel, or using various bat shapes and sizes, this technique can be customized to suit your specific needs. To create a stable connection between the bat and the pottery wheel, the clay pad method offers a simple yet effective solution.

Ensuring that your clay is level and smooth is crucial for the successful attachment of the bat. By carefully crafting rings on the clay pad while it spins, you create channels for air to assist in sealing the bat securely onto the wheel. The gentle tap as you spin ensures that your bat sits firmly in place, ready for your pottery creation to unfold without any unwanted wobbling distractions.

How To Remove A Bat From A Pottery Wheel

Using the bat-pin approach for attaching bats to pottery wheels can be incredibly efficient, especially when working with Plastic or Hydro-bats that have convenient rims. The ease of removal by simply lifting the bat off the wheel adds a level of convenience to the pottery process. Speedball Bats, with their snug fit around the bat pin due to a cut-out hole, enhance stability during use but require careful attention when removing them from the wheel.

If you find a bat taking refuge in your pottery wheel, remain calm and don’t panic. First, turn off the pottery wheel to minimize any noise that may scare the bat. Next, carefully cover the entire wheel with a large cloth or towel to create a dark environment that will encourage the bat to leave on its own. It’s important not to try to physically remove the bat as you may harm it unintentionally.

Remember, bats are beneficial creatures that play a vital role in our ecosystem by controlling insect populations. So, treating them with care and respect is crucial. After some time has passed and you believe the bat has left, gently uncover your pottery wheel and inspect it for any signs of the bat’s presence. If necessary, clean the area thoroughly and consider installing safeguards such as covers or netting to prevent future unwanted visitors from getting inside your pottery equipment.

How To Store Pottery Wheel Bats

Proper storage of pottery wheel bats is essential to ensure their longevity and usability. Storing them standing up on one edge, similar to dishes in a dish rack, helps prevent any warping or damage. Taking the time to clean off any clay residue and allowing the bats to dry before storing them can also help maintain their quality over time.

Consider investing in a Bat Storage Cart or choosing a moisture-free space for vertical storage. Think about the size of the bats you use based on the type of pottery you create, as larger bats may require more storage space than smaller ones. One common mistake many potters make is stacking the bats on top of each other, which can lead to warping or cracking. Instead, consider storing them vertically in a dedicated rack or holder to prevent any unnecessary pressure.

Another important tip is to keep the bats in a cool, dry place away from direct sunlight. Excessive heat and moisture can damage the wooden bats and affect their shape. Periodically inspect your pottery wheel bats for any signs of wear or damage and address issues promptly to extend their lifespan.

Conclusion

Utilizing bats on a pottery wheel can greatly enhance your ceramic work by providing stability and efficiency during the throwing process. Understanding the different types of bats available, such as plaster, plastic, and wooden bats, allows for versatility in usage based on specific project needs.

Proper storage of bats is crucial to ensure their longevity and effectiveness for future use. By incorporating bats into your pottery practice, you can streamline your workflow and achieve consistent results in your creations. Take the time to explore different bat options and techniques to maximize your pottery wheel experience and elevate your craftsmanship.

FAQs

What Kind Of Wood Do You Use For Pottery Bats?

Pottery bats are typically made from Baltic birch plywood, known for its durability and resistance to warping. Masonite (hardboard) and maple are also commonly used for their smooth surfaces and stability.

Why Use A Bat On A Pottery Wheel?

Using a bat on a pottery wheel allows for easy removal and transportation of your work without disturbing its shape. It also enables you to work on multiple pieces consecutively without having to wait for each to dry.