Pinholes in Pottery Glaze – 6 Causes and Simple Solutions

With its ancient roots and timeless allure, pottery has long captured our fascination with its beauty and functionality. Each piece tells a story of craftsmanship, creativity, and tradition.

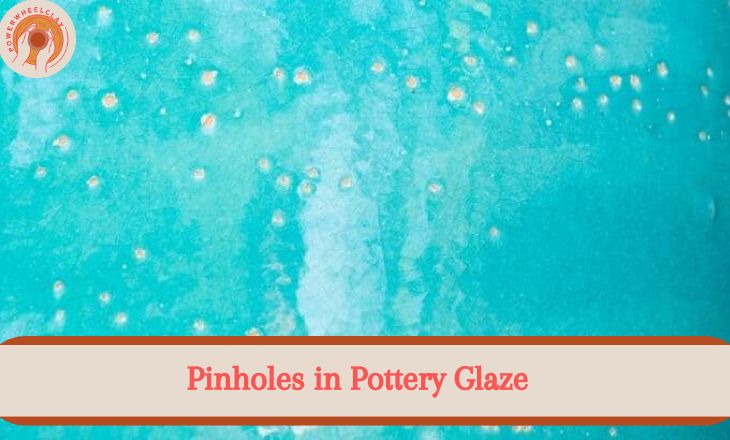

Hidden within the glossy finish of glazed pottery lies a mysterious flaw that has puzzled artisans for centuries: pinholes. These tiny imperfections may seem insignificant to the untrained eye, but they hold the key to understanding the delicate balance between artistry and science in ceramics.

We will delve into the intriguing world of pinholes in pottery glaze – exploring their causes, implications, and potential solutions to preserve the integrity of these exquisite art pieces.

What is a Pinhole In Pottery Glaze? The Diagnosis

A pinhole in pottery glaze refers to a small hole or pit that appears on the glazed surface of a ceramic piece after firing. Pinholes are often caused by trapped air bubbles or impurities within the glaze itself, which expand and create voids during the firing process.

To diagnose the root cause of pinholes in pottery glaze, it is important to consider factors such as the composition of the glaze, firing temperature, and application technique. firing too quickly or at high temperatures can also contribute to the formation of pinholes as gases are unable to escape efficiently.

Addressing pinholes in pottery glaze requires careful attention to detail during both the preparation and firing stages. By ensuring proper mixing and application techniques, as well as experimenting with different firing schedules and temperatures, potters can minimize the occurrence of pinholes and achieve a smoother, more professional finish on their ceramic creations.

What Causes Pinholes in Pottery Glaze?

Pinholes in pottery glaze can be a frustrating and common issue for many ceramic artists. These tiny holes, which appear as small dots or imperfections on the glazed surface, are often caused by trapped gases escaping during the firing process. While pinholes may seem like a minor aesthetic flaw, they can also pose concerns about the food safety of glazed ceramics.

One possible cause of pinholes is incomplete drying of the greenware before bisque firing. Moisture trapped in the clay body can turn into steam during firing, leading to bubbles that create pinholes in the glaze.

To address concerns about the pinholes in glaze food-safe in ceramics, it’s recommended to test them for leaching using food-safe testing methods. While some sources suggest that pinholes could potentially harbor bacteria if not properly sealed, ensuring that your pottery is properly fired and glazed according to recommended practices can help minimize these risks.

Gases and Pinholes

When it comes to the realm of photography, glaze pinholes are often underestimated yet hold a fascinating secret. These tiny holes can alter the behavior of gases, especially in enclosed spaces. As light passes through a pinhole camera, it creates stunning images by manipulating how gases react within the chamber.

The unique properties of gases when interacting with pinholes have not been fully explored. By delving deeper into the intricacies of gas behavior about pinholes, we may uncover innovative ways to harness these natural processes for our benefit.

Is Your Choice of Clay Causing Pinholes in Your Pottery Glaze?

One of the common reasons for pinholes in pottery glazes could be the choice of clay. Some clays contain impurities or particles that can create pockets of air when fired, leading to pinholes in the glaze.

Choosing high-quality clay with minimal impurities can help reduce the occurrence of pinholes. It’s important to consider the source and composition of your clay to ensure a smooth and consistent finish on your pottery pieces.

The firing process is crucial in preventing pinholes in glazes. Properly bisque-firing the clay before applying the glaze can help eliminate any trapped air or moisture that may cause pinholing.

Experimenting with different firing schedules and techniques can also help you achieve a flawless glaze surface on your pottery pieces. By paying attention to both your choice of clay and firing methods, you can improve the overall quality of your glazed pottery and minimize issues like pinholing.

Choice of Glaze

When choosing the perfect glaze for your pottery, it’s important to consider both aesthetics and functionality. While glossy glazes can add a beautiful shine to your piece, matte finishes offer a more subtle and understated look.

Keep in mind that different glazes may react differently when fired, so it’s essential to test them beforehand on small pieces of clay. The choice of glaze should complement and enhance the design of your pottery, creating a harmonious blend of form and finish that captures the essence of your creative expression.

Adjusting The Glaze Fire to Prevent Pinholes in Your Pottery Glaze

One effective strategy to avoid pinholes in your pottery glaze during the final firing stage is to adjust the temperature and duration of the glaze fire. Pinholes often occur when gases are released from the clay body or glaze too rapidly, creating small craters on the surface of the pottery.

Another important factor to consider is proper ventilation throughout the firing process. Inadequate ventilation can lead to poor gas release and an increased likelihood of pinholing in ceramics. By ensuring good airflow within your kiln, you can promote a more uniform distribution of heat and gases, ultimately improving the quality of your finished pottery pieces.

Conclusion

Understanding the causes of pinholes in pottery glaze can help ceramic artists troubleshoot and prevent this common issue. By addressing factors such as improper glaze application, contamination, or firing temperature inconsistencies, artists can achieve smoother and more professional results.

Pinholes in pottery glaze can be a frustrating issue for ceramic artists. By understanding the six common causes of pinholes and implementing the simple solutions provided in this article, artists can greatly improve the quality of their finished pieces. Artisans are encouraged to apply these tips and techniques in their practice to achieve optimal results in their ceramic creations.

FAQs

What Causes Pinholes in Glaze?

Pinholes in glaze are commonly caused by trapped air bubbles that are not properly removed during the forming and drying process. If this air is not released through proper wedging or kneading techniques, it can create small pockets within the clay that result in pinholes after firing.

Why Are There Holes In Pottery?

These holes help release any trapped air or moisture during the firing process, preventing the pottery from cracking or exploding in the kiln. Holes can also be used to create a more even distribution of heat during firing, ensuring that the piece is fired uniformly.

How To Fix Pinholes In Glaze?

To fix pinholes in glaze, refire the piece, as a second firing can often eliminate them. Adjust the glaze formula by increasing flux or adding a small amount of bentonite to reduce pinholing. Slow the firing process with a longer soak at peak temperature to allow trapped gases to escape.

Ensure the clay body is well-prepared, free of impurities, and properly wedged. Refine surface preparation by wiping bisque ware with a damp sponge before glazing to remove any dust or debris.

Are Pinholes In Glaze Food Safe?

Pinholes in glaze can compromise food safety, as they create tiny openings that may trap bacteria and make the surface difficult to clean. If the pinholes are deep enough to expose the underlying clay body, the piece may absorb moisture and harbor bacteria, making it unsafe for food use.

To ensure food safety, it’s best to refire the piece to eliminate the pinholes or avoid using it for food if the defects persist.