DIY Propane Kiln Ideas – 4 Easy Ways to Make a Propane Kiln

When it comes to creating your Diy propane kiln ideas for pottery or metalworking, there are endless possibilities for DIY enthusiasts. One popular method is to repurpose a gas grill by removing the cooking grate and lining the inside with firebricks to create a makeshift kiln. This allows for easy temperature control and can be a cost-effective option for beginners.

How to Make a Propane Raku Kiln

When it comes to creating your own propane Raku kiln, there are a few key steps to keep in mind. First, start by acquiring the necessary materials: a metal trash can, propane burner, fire brick or kiln shelf for the base, and heat-resistant gloves.

Assemble the trash can with vents near the bottom for air circulation and place the kiln shelf inside as a platform for your pieces. Then, connect the propane burner to a gas source and carefully light it to begin heating your kiln. Raku pottery, a traditional Japanese ceramic firing technique, has gained popularity in recent years for its unique and unpredictable results.

For a successful firing process, monitor the temperature carefully using an infrared thermometer and adjust the heat level as needed. Experiment with different firing techniques such as reduction or oxidation to achieve unique glaze effects on your pottery pieces.

Making a DIY Propane Kiln

Creating your propane kiln can be a rewarding and cost-effective project for those interested in ceramics or metallurgy. The key components include a durable metal container, a burner assembly, and insulation materials to ensure even heat distribution. By carefully following instructions and safety guidelines, you can customize the size and design of your kiln to suit your specific needs.

One advantage of a DIY propane kiln is its flexibility in terms of temperature control and firing techniques. With practice and experimentation, you can achieve different effects on your clay or metal projects by adjusting the heat level and firing duration. building your kiln allows for a deeper understanding of the firing process, leading to more informed decisions when working with various materials.

With a little bit of research and the right materials, constructing a DIY gas kiln can be a rewarding and cost-effective project.

A Trash Can DIY Propane Kiln

With a bit of creativity and some time investment, you can easily turn a simple trash can into a functional propane kiln for all your pottery projects. By adding a burner to the bottom and strategic vent holes around the sides, you can create the perfect environment for firing clay at high temperatures. This DIY approach not only saves money compared to buying a commercial kiln but also allows for customization to suit your specific needs.

Insulating Your Trash Can Kiln

Insulating your trash can kiln is a crucial step in optimizing its efficiency and maintaining consistent firing temperatures. By adding a layer of insulation such as a ceramic fiber blanket or refractory bricks, you create a barrier that helps retain heat within the kiln, allowing for more even heating throughout the firing process.

This insulation not only improves energy efficiency but also reduces heat loss, ultimately saving you time and money in the long run.

Adapting the Trash Can

Have you ever thought about turning your trash can into a stylish and functional piece of decor? By adding a coat of paint or decorative vinyl, you can easily transform a boring plastic bin into a statement piece that complements your home decor. Consider incorporating storage compartments or hooks on the outside of the trash can to hang small items like bags or utensils for added convenience.

Using the Trash Can Kiln

Imagine turning a simple trash can into a kiln, a tool to unleash your creativity and craft stunning pottery pieces. The Trash Can Kiln method may sound unconventional, but its results are nothing short of magical. This DIY approach allows you to experiment with different firing techniques and achieve unique finishes that traditional kilns might not offer.

With some insulation materials, a basic understanding of firing temperatures, and a little bit of patience, you can transform humble clay into exquisite works of art. One of the key advantages of using a propane pottery kiln is the speed at which it can reach high firing temperatures.

The Top Hat Trash Can Kiln

The Top Hat Trash Can Kiln is a fascinating DIY project that combines creativity with functionality. With just a few simple materials like a metal trash can, some fire bricks, and a propane burner, you can create your mini gas kiln design and firing or pottery. The unique design of the top hat shape allows for better temperature control and heat distribution, resulting in more consistent firing results.

Using the Top Hat Kiln

The Top Hat Kiln is a versatile and reliable tool for ceramic artists looking to elevate their craft. Its unique design allows for even heat distribution, resulting in more consistent firing results. One of the key advantages of the Top Hat Kiln is its vertical loading chamber, which maximizes space efficiency and allows for larger projects to be fired with ease.

Another benefit of using the Top Hat Kiln is its energy efficiency. The vertical design of the kiln helps to minimize heat loss during firing, ultimately reducing energy consumption and operating costs.

The use of a propane ceramic kiln offers artists and craftsmen a convenient and efficient way to fire their creations. Unlike traditional wood-fired kilns, propane kilns provide more control over temperature and firing conditions, resulting in consistent and reliable outcomes.

A Wire Mesh DIY Propane Kiln

Creating a DIY propane kiln using wire mesh opens up a world of possibilities for artists and craftsmen looking to explore the art of ceramics and pottery. The versatility of wire mesh allows for precise control over the shape and size of the kiln, giving creators more freedom to experiment with different firing techniques and temperatures.

By customizing the design and dimensions of the kiln, artisans can tailor it to fit their specific needs and projects, resulting in unique and personalized pieces.

Making a Wire Mesh DIY Propane Kiln

Creating a wire mesh DIY propane kiln can be a fun and practical project for those interested in pottery or metalworking. The use of wire mesh allows for better heat distribution within the kiln, ensuring that items are fired evenly and thoroughly. By constructing your own kiln, you have the flexibility to customize its size and shape to suit your specific needs and space constraints.

Different Wire Mesh Designs

Wire mesh designs are not only functional but can also be incredibly visually appealing. One popular design is the diamond mesh pattern, which offers a classic and elegant look while providing strong structural support. This type of wire mesh is commonly used in fencing, security screens, and architectural applications, adding both style and functionality to various projects.

Another interesting wire mesh design is the crimped wire pattern, which features crimped wires that intersect at regular intervals to create a unique texture. This design is often used in decorative applications such as room dividers, window screens, and artistic installations.

A Shopping Cart DIY Propane Kiln

Imagine being able to create your own beautiful ceramics right in the comfort of your backyard with a shopping cart DIY propane kiln. This innovative project allows you to transform a simple shopping cart into a fully functional kiln that can reach high firing temperatures ideal for pottery making. With this DIY approach, you not only save money on purchasing a traditional kiln but also have the satisfaction of customizing your own unique creation.

The process of converting a shopping cart into a propane kiln may seem unconventional at first, but it opens up endless possibilities for creativity and self-expression. By repurposing everyday materials like firebricks and propane burners, you can unleash your inner artist and experiment with different firing techniques to achieve stunning results in your ceramic work.

Heating the Shopping Cart Kiln

Heating the shopping cart kiln is a delicate process that requires precision and care. The kiln must be brought up to the ideal temperature gradually to prevent any damage to the materials inside. One key factor to consider is ensuring even heating throughout the entire kiln, as hot spots can lead to uneven firing and potential product flaws. It’s essential to monitor the temperature closely and make adjustments as needed to maintain a consistent heat level.

Brick-built DIY Propane Kiln Ideas

Imagine the satisfying feeling of creating your own pottery in a brick-built DIY propane kiln. Harnessing the power of fire to transform raw clay into intricate masterpieces is both exciting and rewarding. The process of loading up the kiln with your carefully crafted pieces, firing it up, and eagerly awaiting the reveal of your creations evokes a sense of anticipation like no other.

The beauty of a brick-built DIY propane kiln lies in its versatility and affordability. With some basic construction skills and materials, you can build a functional kiln right in your backyard or studio space. This hands-on approach not only allows for customization based on your specific needs but also provides an intimate understanding of how the kiln operates, fostering a deeper connection to your craft.

Insulating the Brick DIY Propane Kiln

When it comes to insulating a DIY propane kiln, using fire bricks and ceramic fiber blankets can be a winning combination. Fire bricks are excellent for retaining heat, while the ceramic fiber blanket provides additional insulation to ensure even temperature distribution. By layering these materials inside the kiln, you can create a highly efficient system that will maximize energy savings and improve firing results.

Conclusion

Creating a propane kiln for your DIY projects can be rewarding and cost-effective. You can find a solution that fits your skill level and budget by exploring the four easy ideas presented in this article. Whether you choose to build a simple brick kiln or opt for a more advanced design, the possibilities for creativity are endless.

With careful planning and attention to safety guidelines, you can enjoy the convenience and efficiency of using a propane kiln in your crafting pursuits. Take the first step today and start building your own propane kiln to enhance your artistic endeavors.

FAQs

What Is A Gas Kiln?

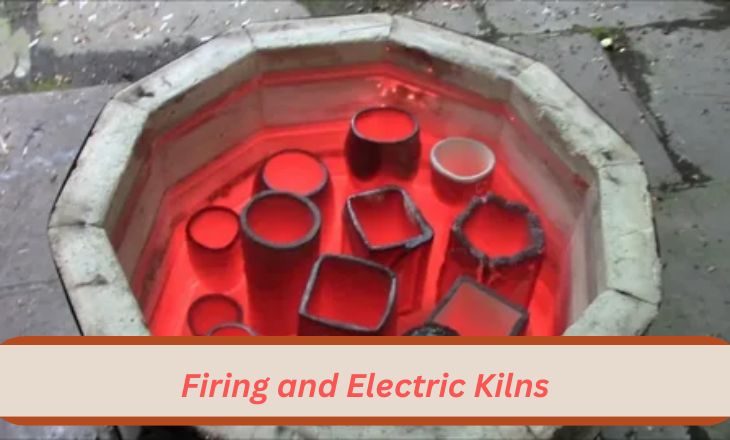

A gas kiln is a type of kiln used for firing pottery or ceramics that is fueled by gas instead of electricity or wood. It consists of a chamber where the pottery pieces are placed to be fired.

How Hot Can A DIY Kiln Get?

A DIY kiln can reach temperatures of up to 2000 degrees Fahrenheit, depending on the materials used and the design of the kiln.