Kiln Sitters: Overview, Components & Calibration

The kiln sitter is a critical component in the ceramic firing process. This device consists of a control box that helps maintain the desired temperature inside the kiln.

The kiln sitter is a critical component in the ceramic firing process. This device consists of a control box that helps maintain the desired temperature inside the kiln.

Firing and Electric Kiln is the most critical part of the ceramics process because it is the one thing that makes clay durable, hence ceramic. because electric pottery kilns are readily available and simple to install.

When investing in a kiln for your pottery or ceramic projects, understanding the cost factors involved is crucial. Kiln prices can vary greatly depending on size, type, and features. A small tabletop kiln designed for beginners may cost around $500 to $1000, while larger industrial kilns can range from $5000 to $20,000.

How Much Does a Kiln Cost? So, it’s important to consider ongoing costs such as electricity consumption and maintenance. Energy-efficient models may be pricier upfront but can result in long-term savings.

What size kiln do I need, it’s essential to consider both the size of your pottery projects and your budget. A smaller kiln with a firing chamber between 6-10 cubic feet might be sufficient if you mainly work on small projects like jewelry or ceramics. However, if you frequently work on larger pieces or want more flexibility in firing multiple projects at once, a medium to large kiln with a 15-30 cubic feet capacity would be more suitable.

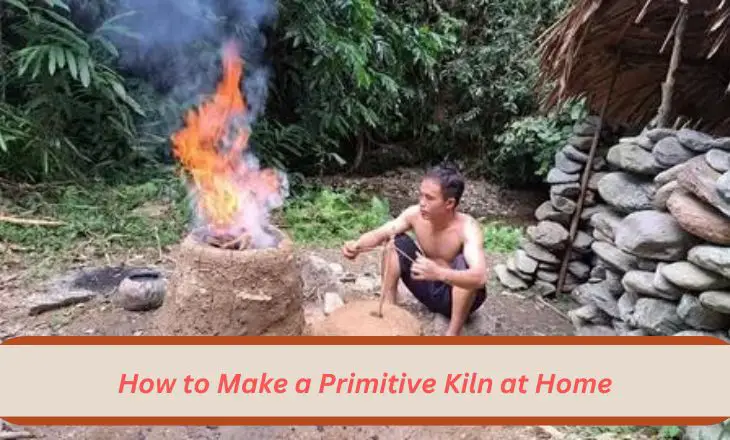

To create a simple pottery Primitive kiln at home find a safe, outdoor location and choose fireproof bricks, clay, or metal barrels. Dig a hole for a pit kiln or build a chamber with an opening for fire and pottery.

Choosing an electric kiln is a significant decision that requires careful consideration of various factors such as size, temperature range, and energy efficiency.

Selecting the right kiln shelves and properly maintaining them is essential for safe and successful electric kiln firings. Here’s a breakdown of each steps. Selecting, maintaining, and cleaning shelves apply generally to any kind of shelves, whether they’re in your kitchen, closet, garage, or even a store.

Exploring the world of no-kiln pottery opens up a whole new realm of possibilities and challenges that can ignite your passion for ceramics like never before.

Is Using an Extension Cord with a Kiln a Good Idea? can i Use an Extension Cord with a Kiln? Learn the dos and don’ts of connecting your kiln to an extension cord for efficient use.

When it comes to creating your Diy propane kiln ideas for pottery or metalworking, there are endless possibilities for DIY enthusiasts. One popular method is to repurpose a gas grill by removing the cooking grate and lining the inside with firebricks to create a makeshift kiln. This allows for easy temperature control and can be a cost-effective option for beginners.